Data Setting Software MEXE02

Simple Settings, Easy Operations

Simple Settings/Easy Operations

Perform basic settings, such as operating data editing and parameter settings.

The AZ series also makes sequence control possible (the built-in controller type only). If operations are simple, this is possible even without a master control system.

At Startup

Unit Setting Wizard

This is a function that allows the traveling amount, speed, etc. to be displayed and input in the units designated by the customer. Units can be displayed to suit the equipment being used, eliminating unit conversion work and simplifying the input of operating data.

Application Example using Sequence Control (Built-in Controller Type only)

Examples of Settings for a Single-Axis Back-and-Forth Operation

This is an operation that combines a loop function and position offset. A programmable controller is not required for repeating back-and-forth operations and operations involving offsetting a fixed amount each time. It is useful for aligned transportation purposes, lifespan testing, and durability testing.

Test Functions

This is a function for confirming connection with the master control system and performing operations with the motor alone. By using it when starting up the equipment, time can be reduced.

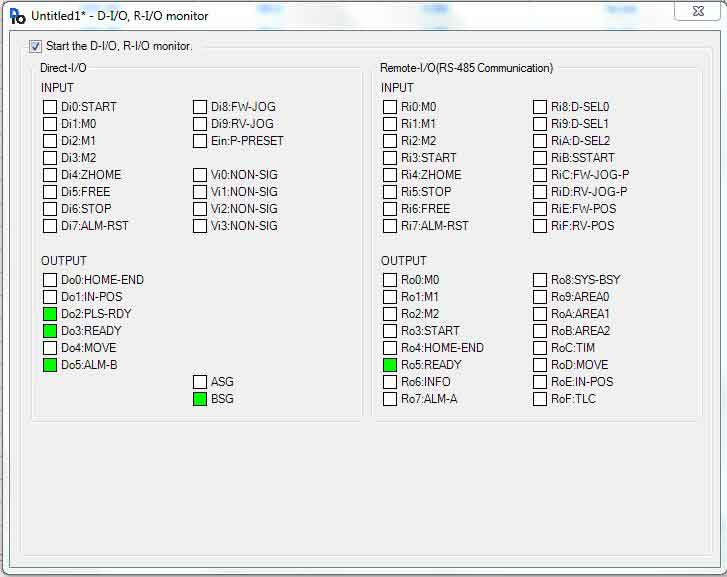

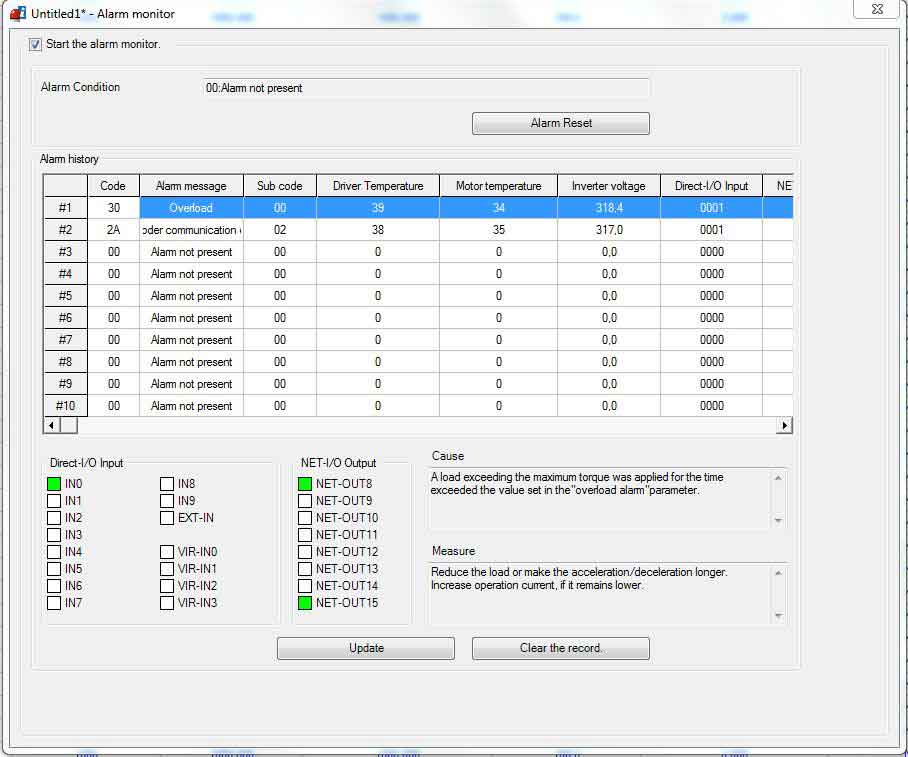

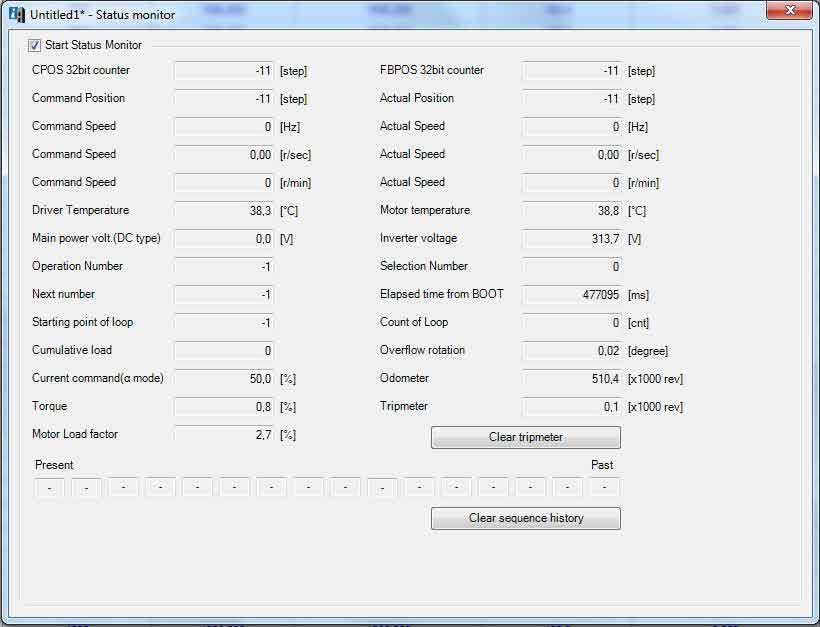

Monitor Function

A variety of monitoring functions are built in for confirming the operating status of the motor, etc. By using them for each situation, equipment start-up and adjustment times can be shortened.