The wiring of stepper motors and actuators can become very extensive. And a higher number of axes lead to higher costs due to more control devices, etc. Furthermore, depending on the control devices and the system network the selection of the suitable drive can be limited.

Simple wiring reduces false wiring and saves time. Connecting to various master systems makes the system configuration smooth and lowers the costs. China Motor provides FLEX products fulfilling those requirements.

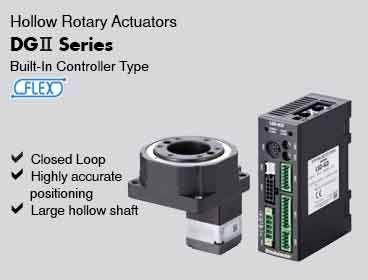

FLEX is a generic name of the products which support Industrial Network control via I/O control, Modbus (RTU) control and network converter. All

FLEX products are marked with the logo

FLEX stepper motor and driver packages are equipped with an integrated controller. Operating data is set in the driver, i.e. no positioning module or pulse generating module are necessary.

You can select the best method: I/O control, Modbus (RTU) control, Industrial Network (via network converter).

Since operating data is set in the driver, the motor can start and stop with hand switches.

Easy Control without the use of a PLC is possible.

The motor normally starts and stops via I/O, and Modbus (RTU) communication is used when setting the alarm and operating data.

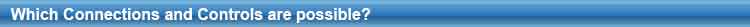

Setting changes as well as monitor and alarm displays are performed on the touch screen (HMI).

If multiple configurations exist, parameters can be entered on

the touch screen, reducing the burden of combining programs

or sequences.

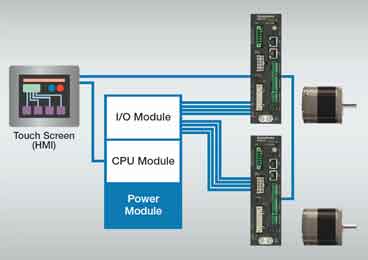

Operating data, parameter settings or operation

commands can be input via RS-485 communication. A maximum of 31 drivers can be connected to one serial communication module. There is also a group sending function for simultaneously starting multiple axes. The protocol is compatible with Modbus (RTU) and can be easily controlled via PLC.

By using a network converter (sold separatly), EtherCAT, CC-link or MECHATROLINK communication is possible. Operating data, parameter settings or operation commands can be input via various types of communication. Since it can flexibly accommodate the networks specified by the end user, design time is shortened.

More FLEX speed control motors and actuators will be lined up in the future.