FAQ

This area is where you will find answers to the most frequently asked technical

questions on the stepping motor, asynchronous motor and fan product groups.

This area is frequently updated.

The motor gets extremely hot. Is this all right?

The internal loss generated when the motor converts electrical energy to rotational movement becomes heat, making the motor hot. The motor temperature is expressed as the ambient temperature plus the temperature rise caused by loss within the motor. If internal loss within the motor is 50°C and the ambient temperature is 30°C, the surface of the motor will be 80°C. This is not abnormal for a small motor.

Will large fluctuations in power supply voltage affect the motor?

The torque produced by the motor is affected by changes in power supply voltage. The torque produced by the motor is proportional to roughly the square of the power supply voltage. For example, if the voltage of a motor rated at 230 V fluctuates between 207 V (90%) and 253 V (110%), the torque produced will vary between 80% and 120%. When using motors under large power voltage fluctuations, remember that the torque produced will vary, so select a motor that provides a sufficient margin.

Can a reversible motor be used as an induction motor if the brake shoe is removed?

A reversible motor is not simply an induction motor with a simple braking mechanism added. The ratio of coils between the primary and the secondary coils in a reversible motor is different from that of an induction motor. The simple brake mechanism is added to the rear of the motor. The capacitor’s capacitance is also increased to increase the starting torque. This means that if only the brake mechanism is removed, the reversible motor will not be usable at a continuous rating like an induction motor; it will simply lose its holding power and its reversing characteristics will be reduced.

What does it mean to say that a reversible motor is rated for 30 minutes?

Reversible motors require a larger input power than induction motors to increase the starting torque and improve the instant reversing characteristics. This means that loss is high and the temperature rises more during continuous operation. If operated continuously, the motor will burn out. It is thus designed to provide maximum performance if operated for no more than 30 minutes continuously.

Can the speed of induction motors and reversible motors be changed?

The speed of single phase (AC) induction motors and reversible motors is determined by the power supply frequency. To change the speed of induction and reversible motors, the power supply frequency can be changed using inverter control or gears and pulleys can be used. If your application requires changing speed, we recommend a speed control motor.

The connection diagrams shows that a capacitor must be connected. Why is this necessary?

Almost all of China Motor’s standard compact AC motors that fall within the broad group of single-phase induction motors are “capacitor-run-motors”. To run an induction motor, a rotational magnetic field must be created. Capacitors perform the role of creating a power supply with the phase shift that is required for creating such a rotational magnetic field. Three-phase motors, by contrast, always supply power with different phases, so they do not require capacitors.

Can I use a capacitor other than the one that comes with the motor?

The capacitor that comes with the motor has a capacitance that was selected to work optimally with the motor. When another capacitor is used, it should be a motor capacitor with the same capacitance and rated voltage as the capacitor that comes with the motor. Electrolytic capacitors may not be used.

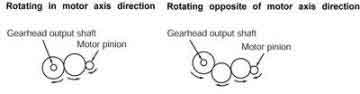

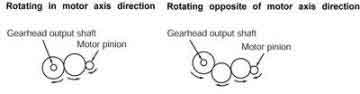

Why do some gearheads output shaft rotate in the same direction as the motor while others rotate in the opposite direction?

Gearheads reduce the motor speed by 1/3 to 1/180. They do not, however, reduce the speed with a single gear, but with several. The number of speed reductions depends on the gear ratio, so the direction of output shaft rotation differs.

The motor may be put in an environment of –20°C to –30°C during transport. Will this create a problem?

Extreme changes in temperature may lead to condensation within the motor. Should this occur, parts may rust, greatly shortening the service life. Take measures to prevent condensation.

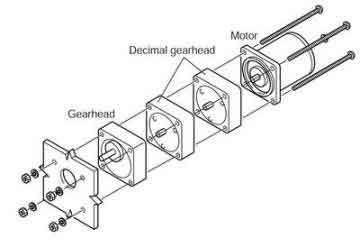

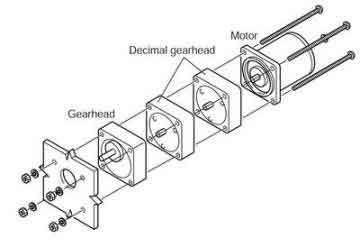

Can gearheads be used to reduce the motor speed to 1:18,000?

A gearhead with a gear ratio of 1/180 must be connected to two decimal gearheads with a gear ratio of 1/10. The permissible torque is the same as if the 1/180 gearhead were used alone. The mounting screws must also be longer.

Do gearheads require oiling?

China Motor lubricates the surface of gears in gearheads with grease. Oiling is not required.

We wired the induction motor according to the wiring diagram, but it does not move. When we turned the shaft by hand, it started to move in the direction we turned it. What could be the cause of this?

In order to turn a single-phase induction motor, it is necessary to use a capacitor to create two power supplies with different phases to obtain the rotating magnetic field. Therefore, if the capacitor is not properly connected, the phenomenon described occurs. Check for a cut line or contact defect in the capacitor section. The way to check is to measure the voltage across the capacitor terminals and check whether or not it is at least 1.5 times the power supply voltage. If not, the capacitor may not be working properly.

Can fans be used above the operating voltage range?

AC and DC fans are designed to be used only within their specified operating voltage range.

Are fans, like motors, equipped with overheat protection devices?

All AC fans in the Orix line that meet UL, CSA and EN/IEC standards either have motors with impedance protection or are equipped with a thermal protector. The DC fans include a current detection function in the drive circuit. In the case of abnormalities, the fan input current is controlled to prevent an increase in temperature and thus guard against burning out the fan motor.

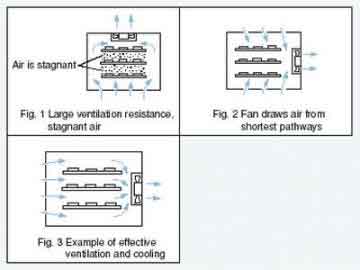

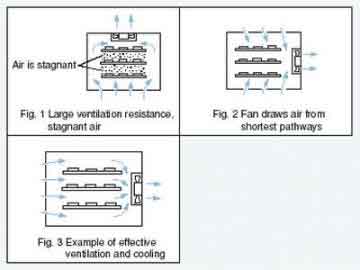

Where should a fan be mounted to achieve the most effective ventilation and cooling?

Three points should be kept in mind when using a fan for ventilation and cooling: 1. Do not increase ventilation resistance (see Fig. 1). 2. Ensure that the air inside the machinery is not stagnant (see Fig. 1). 3. Do not create any shortcuts for air to pass through (see Fig. 2). As shown in Fig. 3 below, the ideal fan position is where air flows in one direction, without interference. If these conditions are met, there is no fundamental difference between forced ventilation and blow ventilation, but exhaust is more effective in maintaining a stable internal temperature.

At how high a temperature can stepping motors be used?

The permissible temperature for the coils is 130°C, since the insulation of the motor is Class B. The motor can be used if the motor surface temperature is 100°C or less. Try to use the motor at lowest temperature possible and mount it to a metal plate that is a good heat conductor, since heat does affect the life of the motor’s ball bearings. Class A insulation (105°C) is a UL/CSA certification condition. When applying for UL/CSA certification as a set, use with a motor case surface temperature no higher than 75°C.

Are there ways to keep the motor temperature down?

There are several ways: 1. Adjust the operating current (a margin of torque must be present, since lowering the current decreases the torque). This suppresses heat generation during operation. 2. Use the driver functions. The “All Winding Off” function and “Automatic Current Cutback” function suppress heat generation when the motor is stopped. 3. Install the motor on a plate with good heat conductivity. 4. Install a fan to cool the motor.

Is there any way to suppress vibration during operation?

There are several ways: 1. Use a clean damper. Vibration is absorbed by internal inert bodies and silicon gel. 2. Adjust the operating current. Vibration can be suppressed by decreasing the torque. 3. Use microstep drive. Use e.g. the RK-Series stepping motor and microstep driver Alpha-Step to suppress vibration. 4. Use geared motors. Geared motors suppress vibration.

Why does the motor move a little when the power is turned on?

The rotor of the motor has 50 teeth and there are 50 locations where it can stop with stability. Depending on where the rotor has stopped before the power is turned on, it may move up to ±3.6°.

Is it all right to machine the motor shaft?

When the shaft is machined, some impact may be felt by the ball bearings within the motor. Therefore, machining is not recommended. On a similar note, do not disassemble the motor. (Disassembling the motor will not only dramatically lower performance, it can also cause it to cease functioning if foreign matter gets inside).

How long can the motor’s lead wires be extended?

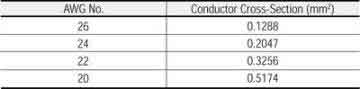

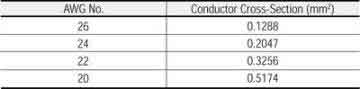

They can be extended to approximately 20m* when a stepping motor is being used. Extending them further may lower the torque’s high-speed characteristics. To extend the leads, use lead wire that has the cross-sectional area for the current values shown in the table below. * Except DC-type and electromagnetic brake type.

How far apart can the driver and controller (pulse generator) be?

The driver of the China Motor stepping motor and driver use photocouplers that are resistant to the effects of external noise, so they may be separated up to approximately 2m. When wiring is involved, always use either twisted pair wire (0.2mm² or larger) or shielded wire for connections and keep it as far away as possible from noise sources.

What is AWG22 motor lead wire?

AWG stands for “American Wire Gauge”. The AWG standards stipulate the core construction and conductor cross-sectional area of lead wires as AWG numbers. The larger the AWG number, the smaller the cross-sectional area. The AWG number is shown on the motor’s external appearance drawing.

© 2017 China Motor Inc. -

Imprint | Privacy Policy | General Terms & Conditions | Shipping costs | Delivery & Payment | Sitemap

*on the list price. The discount is already included in the price and is marked as "Online price“. Only at our web shops.

*on the list price. The discount is already included in the price and is marked as "Online price“. Only at our web shops.